At a Glance

A history of more than 110

years has progressed with

motorization.

years has progressed with

motorization.

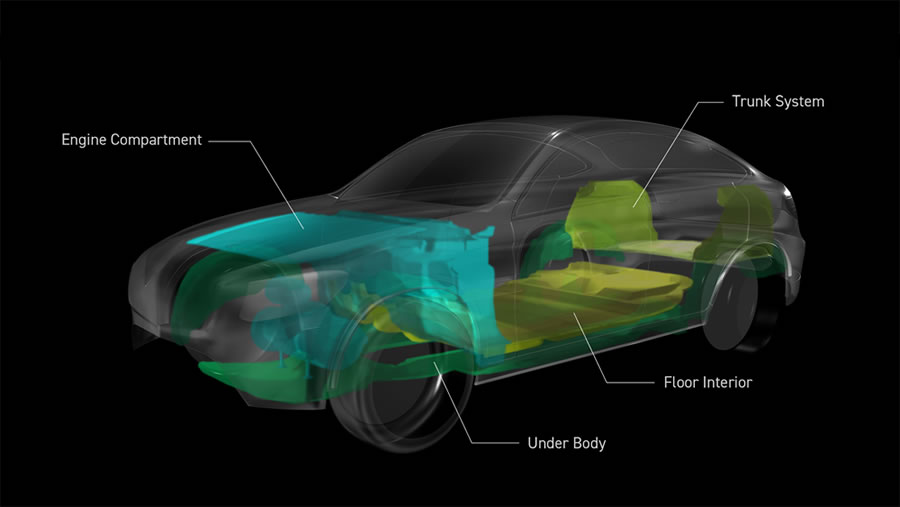

We produce more than

10 million floor carpets

a year.

10 million floor carpets

a year.

Consolidated financial

results is over USD 1.9 billion. as of 2023

results is over USD 1.9 billion. as of 2023

Carpets account for more

than half of the market

share in Japan.

than half of the market

share in Japan.

The group employs 3,700

people around the world,

including the group itself.

people around the world,

including the group itself.

It is supported by the

advanced skills of more than

400 technicians.

advanced skills of more than

400 technicians.

Our development,

production, and sales bases

are spread over 40 locations

worldwide.

production, and sales bases

are spread over 40 locations

worldwide.

News

Certification as “2024 Health and Productivity Management Excellent Company (Large Enterprise Category)”

March 18,2024

View

HAYASHI TELEMPU certified as “2023 Aichi Biodiversity Certified Company”

November 10,2023

View

-HAYASHI TELEMPU proposes a new, free “Van Life”-

Will exhibit HIACE jointly produced with Gifu Auto Body Co., Ltd.

at Messe Nagoya 2023

Will exhibit HIACE jointly produced with Gifu Auto Body Co., Ltd.

at Messe Nagoya 2023

November 2,2023

View

HAYASHI TELEMPU employee Chika Shigesada wins a bronze medal in the Mixed Team category at the World Archery Para Championships

July 24,2023

View

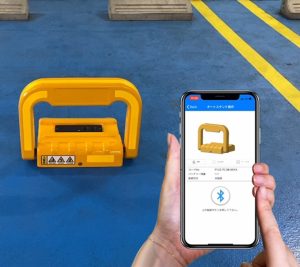

HAYASHI TELEMPU’s “AUTO STAND” system that assists with the DX of parking areas to be used at the new “LEXUS Charging Station” service for LEXUS BEV owners -A charging station that can be reserved in advance to add comfort to owners’ BEV life-

June 16,2023

View

Certification as “2023 Health and Productivity Management Excellent Company (Large Enterprise Category)”

April 6,2023

View

Notice of Changes in Director Framework and Officers

as of April 1, 2023

as of April 1, 2023

April 1,2023

View

HAYASHI TELEMPU realizes online reservations and cashless payments for pay-by-the-hour parking areas at low cost with “AUTO STAND” management system that assists with DX of parking areas

February 13,2023

View

Notice of Changes in Officers as of January 1, 2023

December 28,2022

View